Types of Bearing Materials

Types of Bearing Materials

Blog Article

Have you ever wondered why some machinery operates more smoothly than others? The answer often lies in the choice of bearing materials and designs. These seemingly small components play a critical role in reducing friction, supporting loads, and enhancing the efficiency of mechanical systems. As industries evolve, understanding the nuances of bearing materials becomes essential for engineers and designers seeking to maximize performance and longevity.

Types of Bearing Materials

Bearing materials can be broadly categorized into several types, each with its unique properties and applications. The most common materials include:

- Steel: High-carbon steel is frequently used due to its strength and durability. It's ideal for applications that require high load-bearing capacity.

- Bronze: Known for its excellent wear resistance and low friction properties, bronze bearings are often utilized in marine applications where corrosion resistance is paramount.

- Polymer: Lightweight and resistant to corrosion, polymer bearings are becoming increasingly popular in industries where weight savings are crucial, such as aerospace.

- Ceramic: These bearings offer superior hardness and wear resistance, making them suitable for high-performance applications, including racing and high-speed machinery.

Each material has its advantages and is chosen based on specific operational requirements, such as temperature, load, and environmental conditions. Understanding Bearing Materials and Designs helps in selecting the right type for your needs.

Design Considerations for Bearings

Beyond materials, the design of bearings is equally vital. The configuration of a bearing can significantly impact its performance. For instance, radial bearings are designed to support loads perpendicular to the shaft, while thrust bearings manage axial loads. Here’s a closer look at a few design considerations:

Load Capacity

One of the primary factors in bearing design is load capacity. Engineers must calculate the expected loads during operation to choose a bearing that can handle them without failure. This involves analyzing both static and dynamic loads, which can vary widely based on the application.

Speed Ratings

Bearings are also rated for their maximum operational speed. Exceeding this can lead to excessive heat generation and eventual failure. Factors such as lubrication, material properties, and design geometry influence speed ratings, making it crucial to evaluate these elements during the design process.

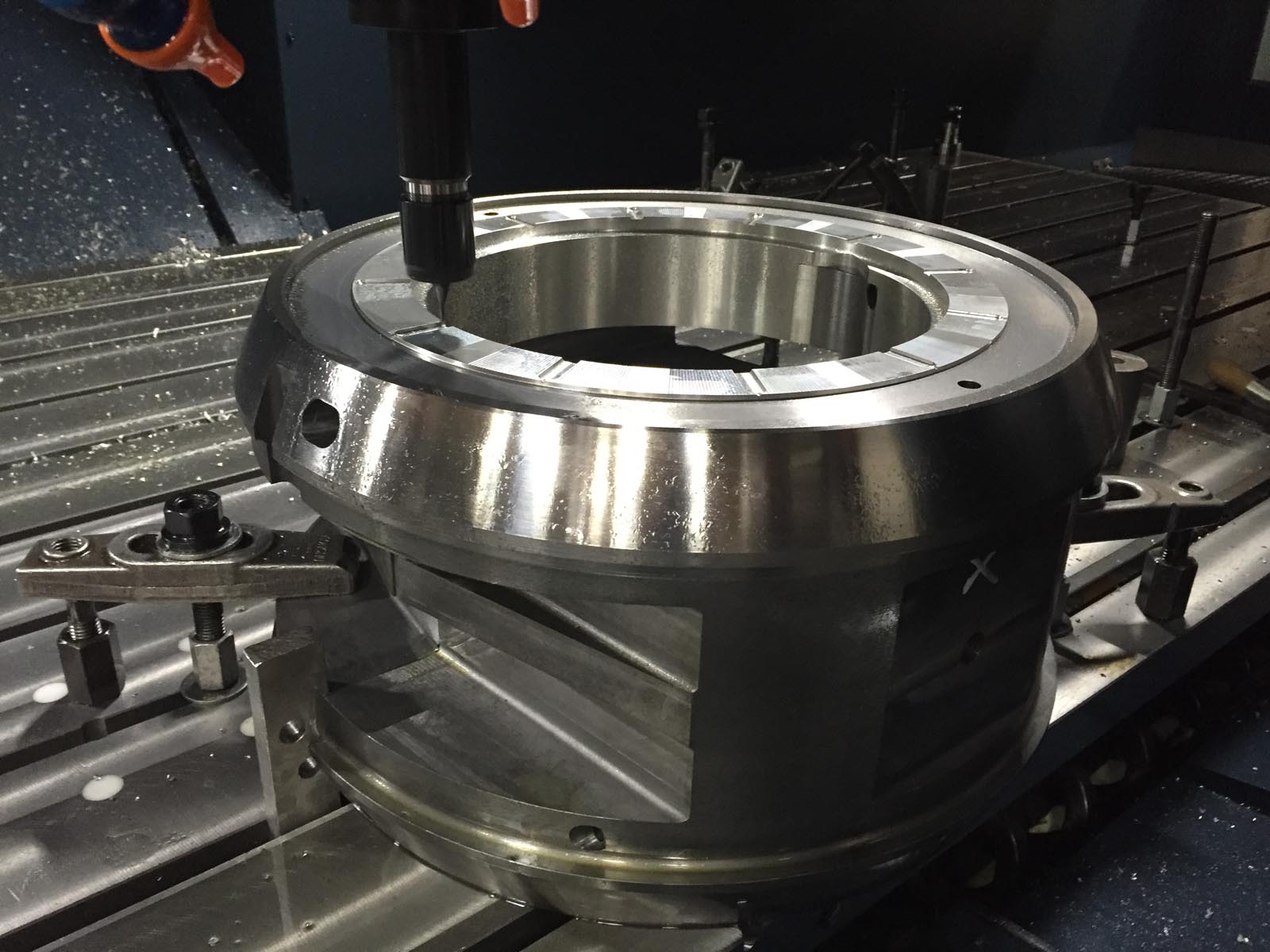

[IMAGE]

Environmental Factors

Bearings often operate in harsh environments, exposing them to dust, moisture, and extreme temperatures. Selecting the appropriate seals and lubrication helps protect bearings from these factors, enhancing their lifespan and reliability.

Innovations in Bearing Technology

The field of bearing technology is continually advancing. Innovations such as hybrid bearings, which combine steel and ceramic materials, are gaining traction due to their improved performance characteristics. Additionally, advances in lubrication techniques, such as self-lubricating bearings, are reducing maintenance needs and enhancing operational efficiency.

Moreover, the integration of smart sensors within bearings allows for real-time monitoring of performance metrics, providing valuable insights into wear and potential failure points. This predictive maintenance approach helps organizations minimize downtime and extend the life of their machinery.

Conclusion

Understanding the intricacies of bearing materials and designs is essential for engineers and manufacturers alike. The right choice of materials and designs not only improves performance but also reduces costs associated with maintenance and replacements. As industries continue to seek greater efficiency and durability, ongoing education in this area will be critical for staying competitive. Whether you're designing a new machine or maintaining existing equipment, a deep dive into bearing technology can unlock new levels of performance.

Report this page